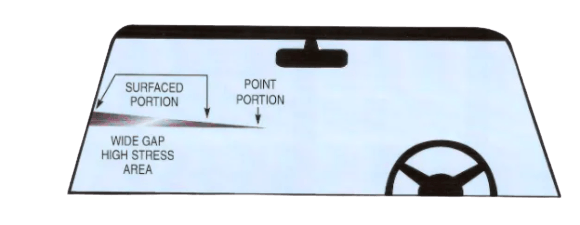

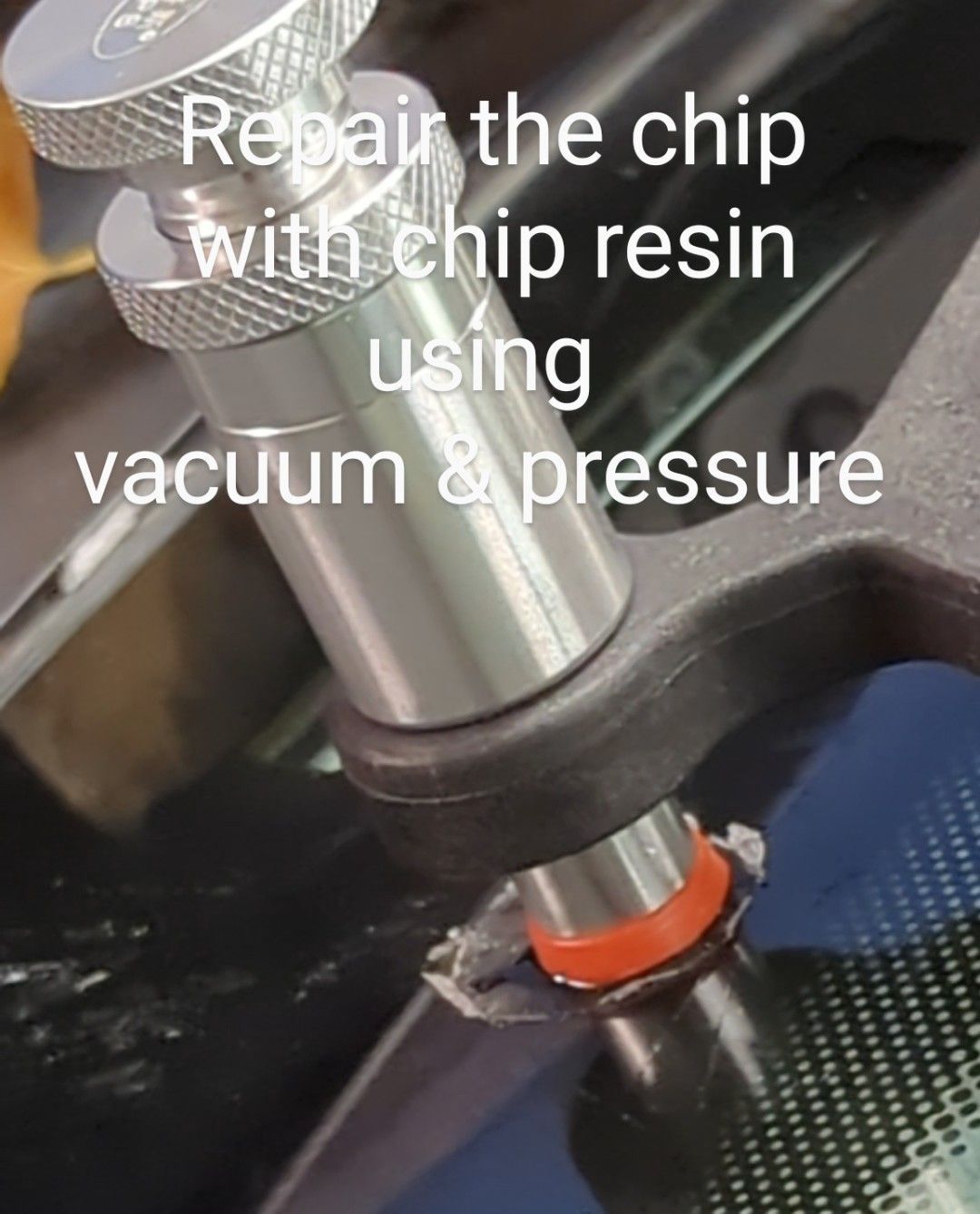

Unsurfaced Crack: Repair using vacuum and pressure.

The unsurfaced crack is very rare. It does not begin or end at an edge of the glass and is therefore also called a "floater".

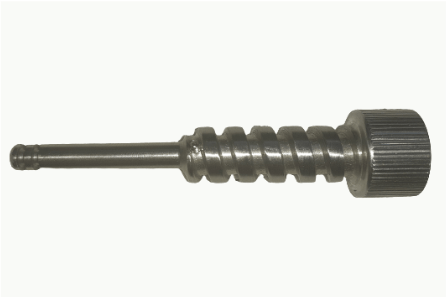

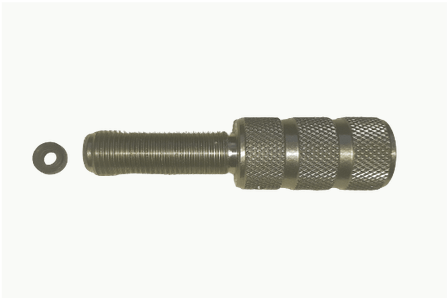

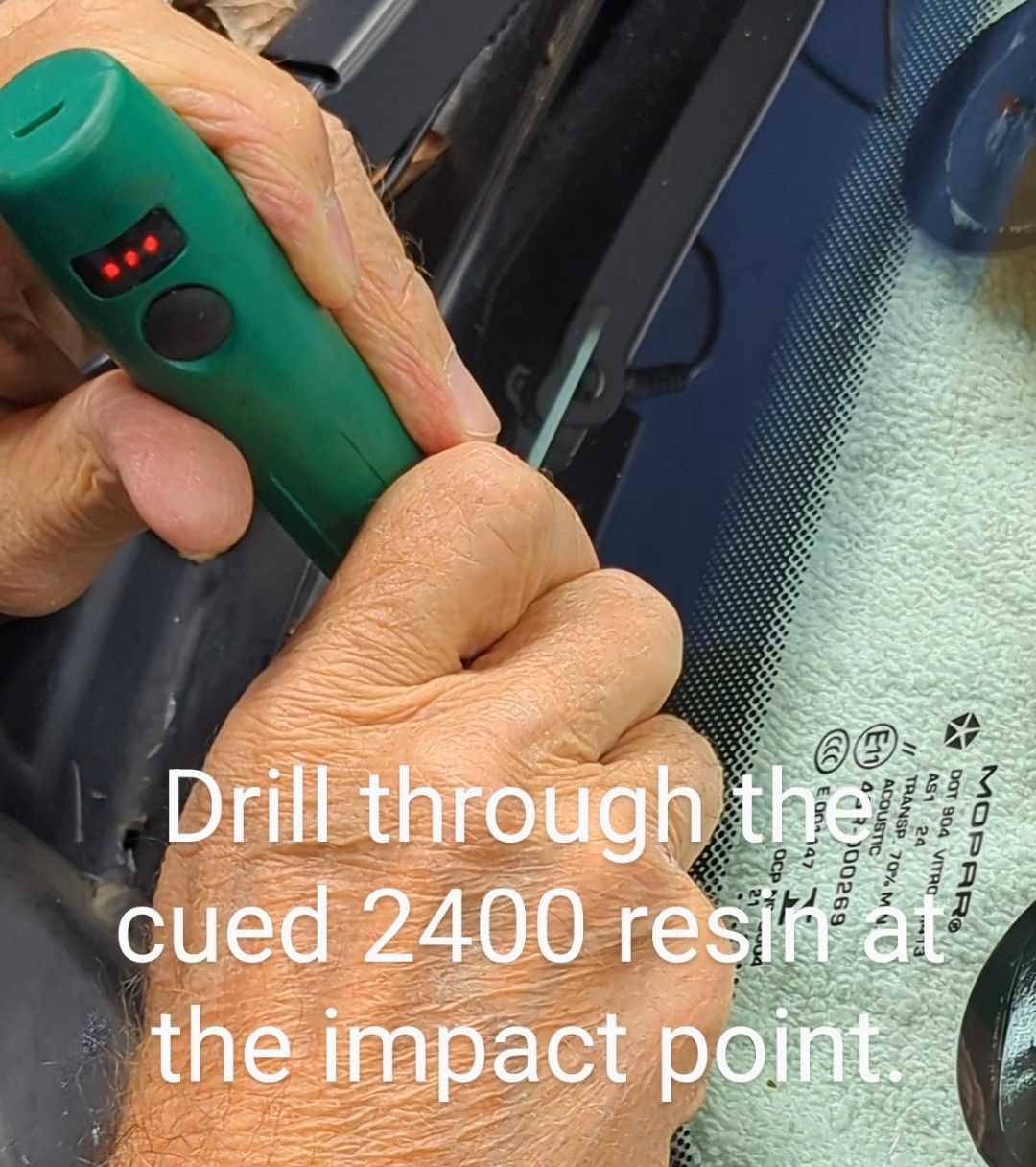

- Drill a hole at one of the points and tap a bullseye.

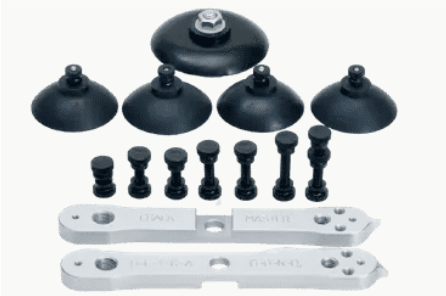

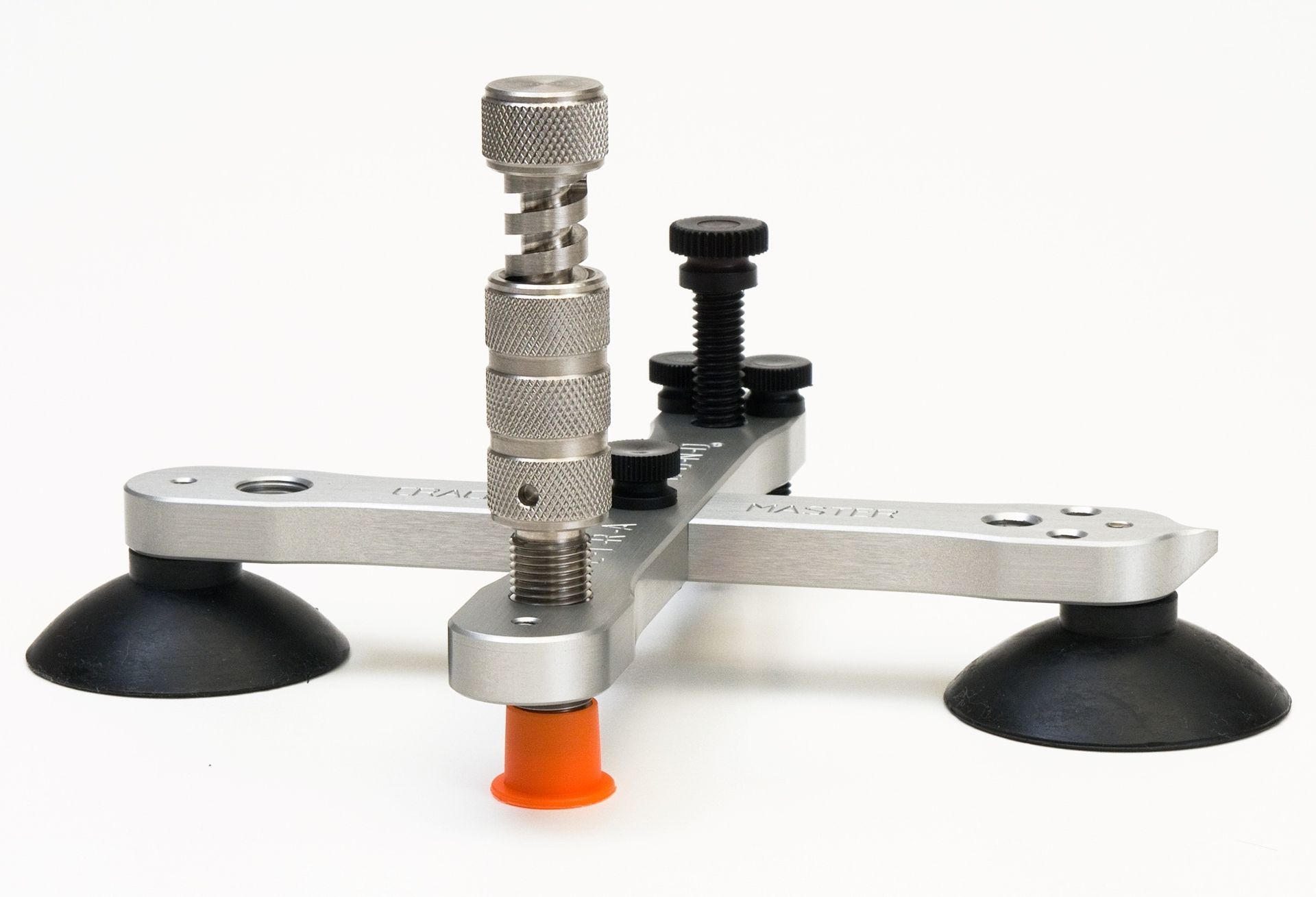

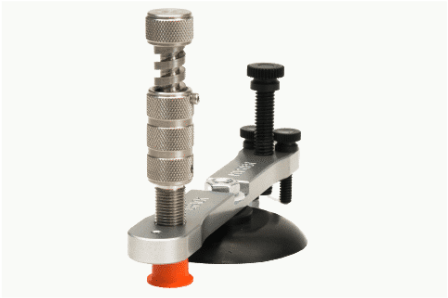

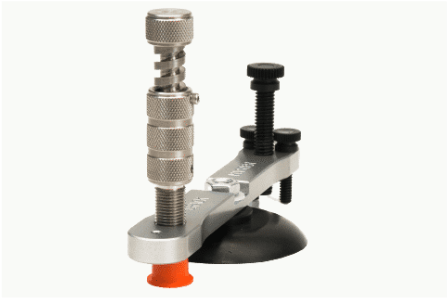

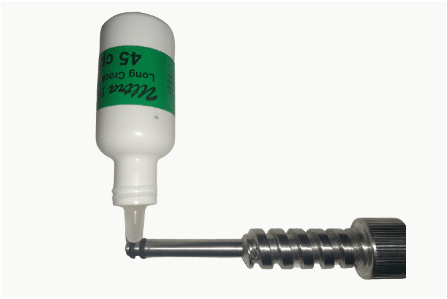

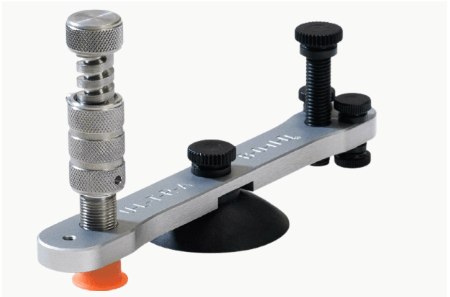

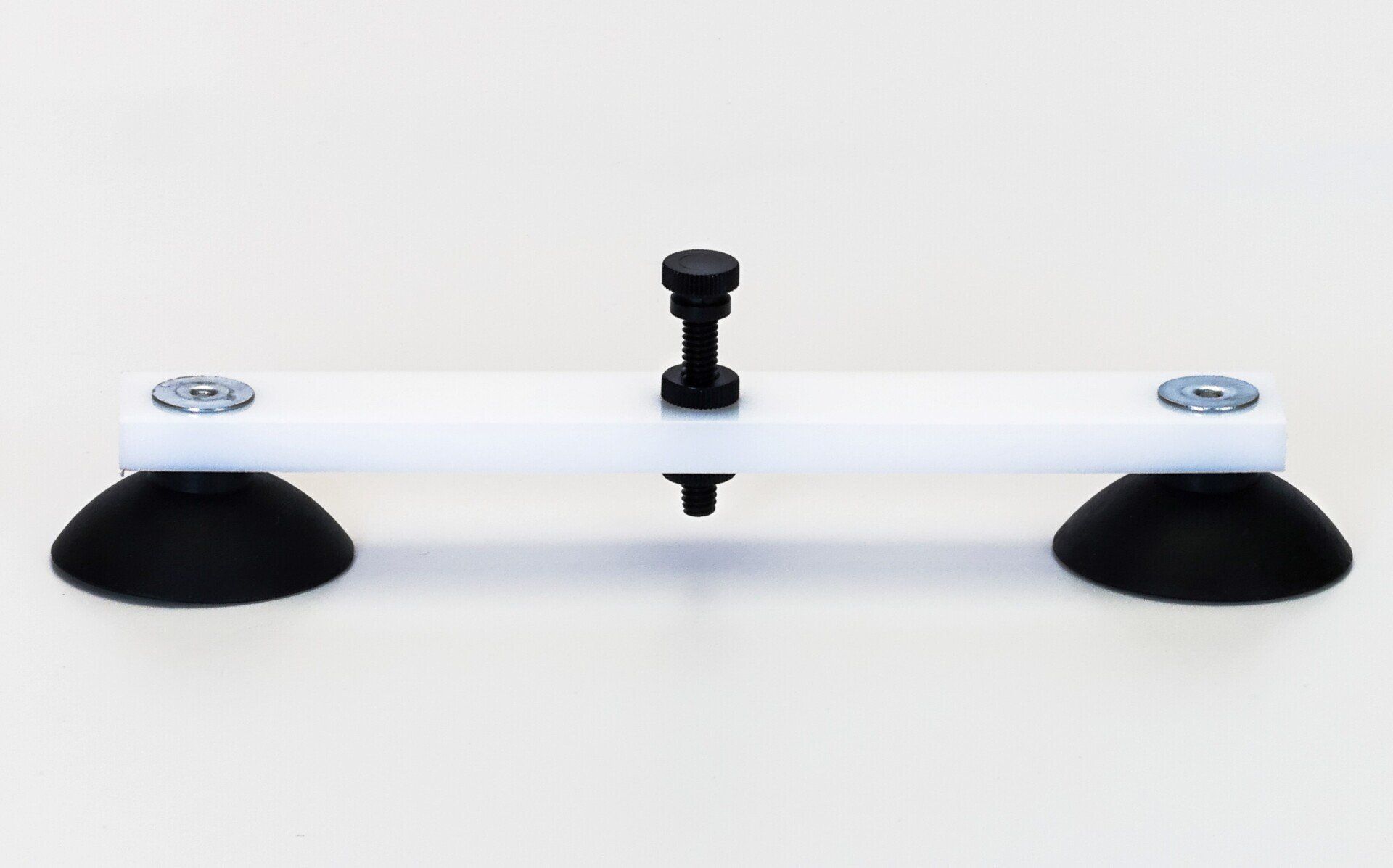

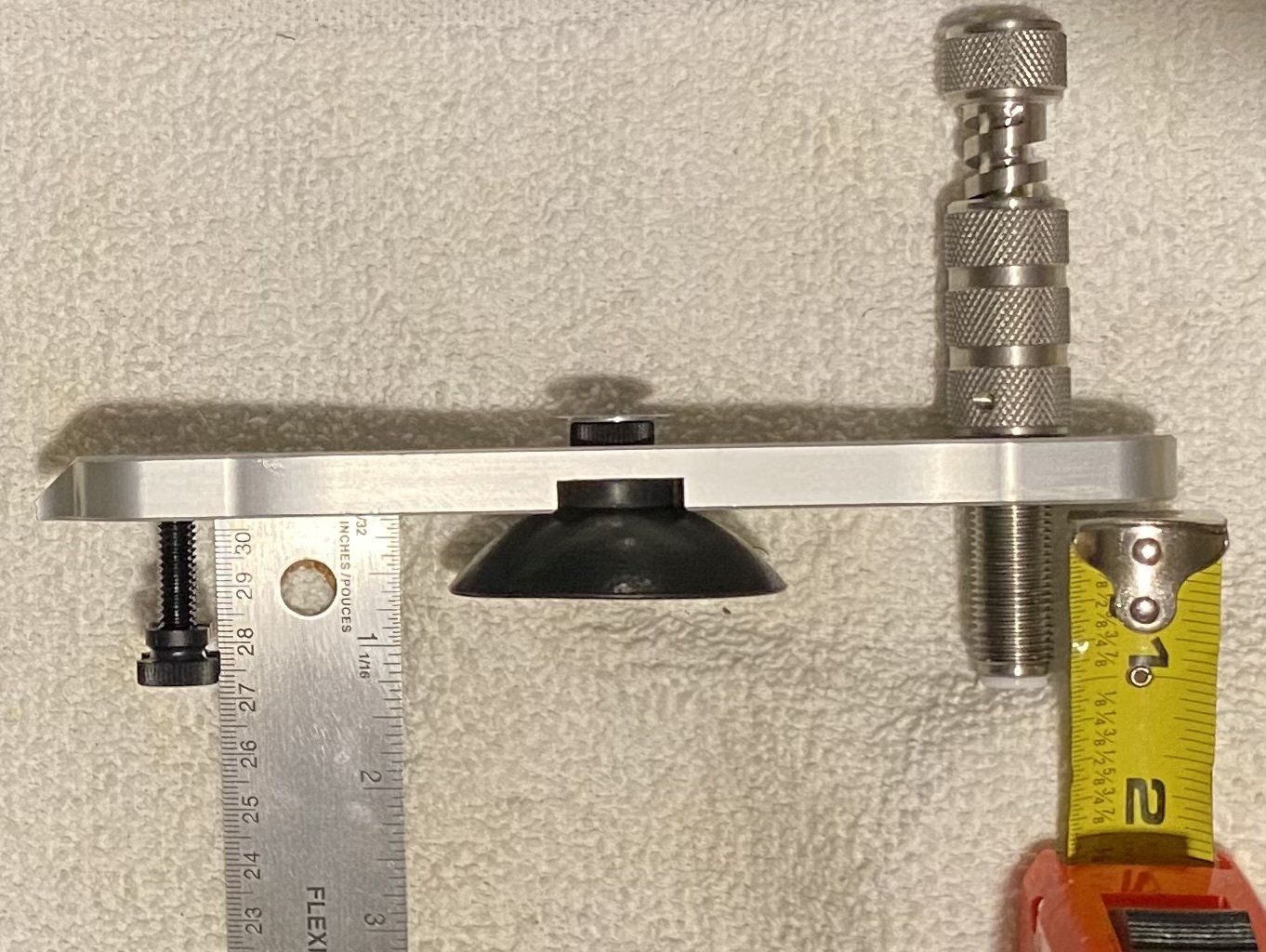

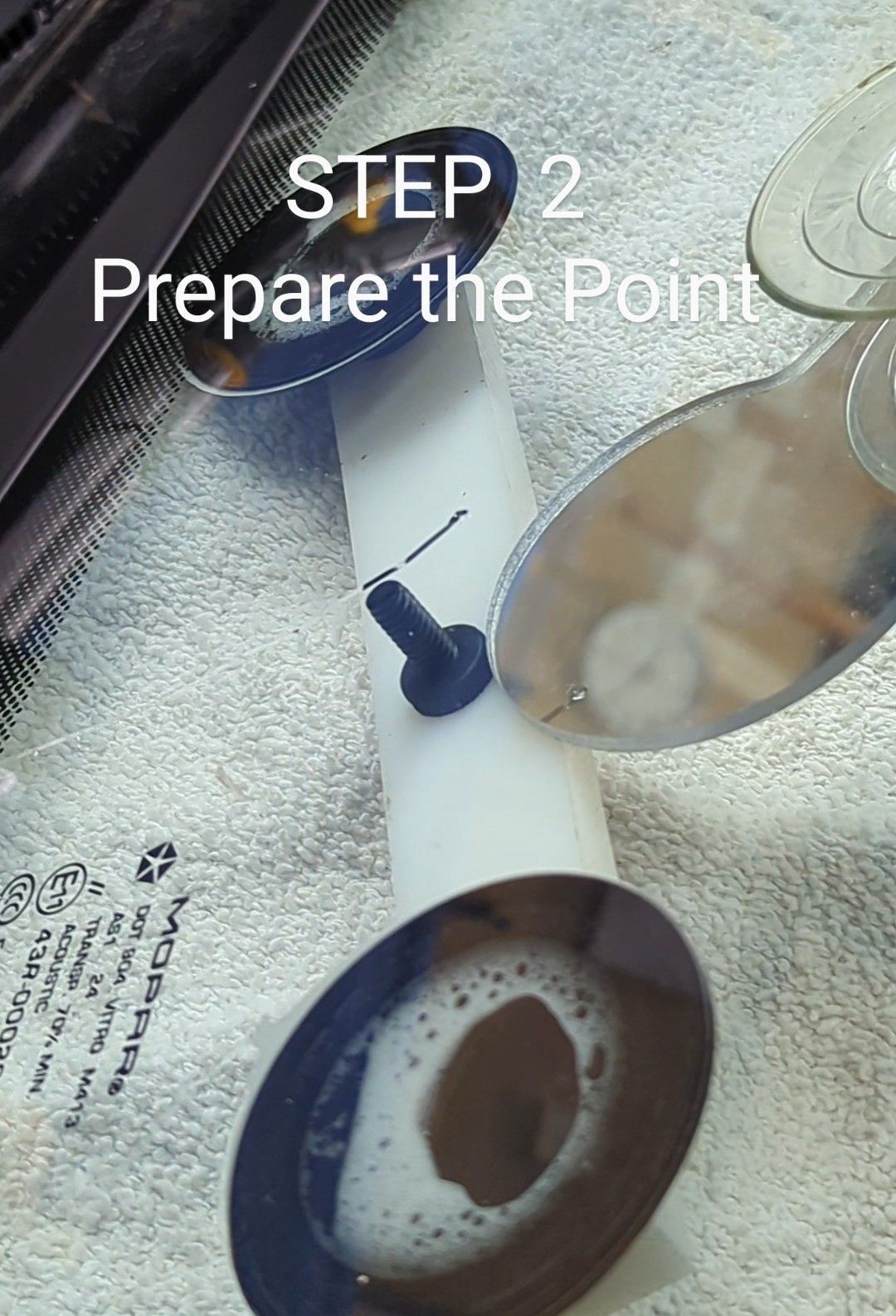

2. Prepare your Bridge structure and fill the bullseye with a low viscosity windshield repair resin (45-100 cps) leaving the injector on pressure.

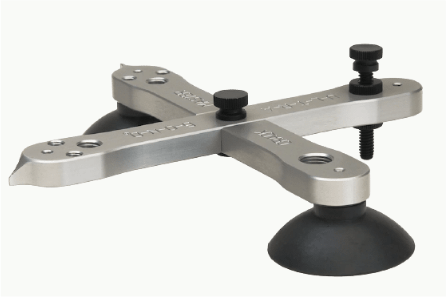

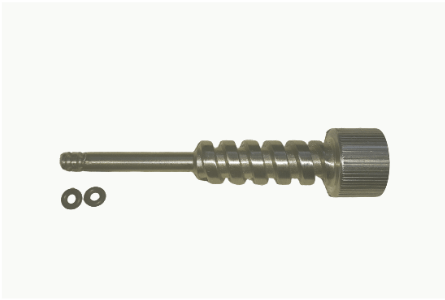

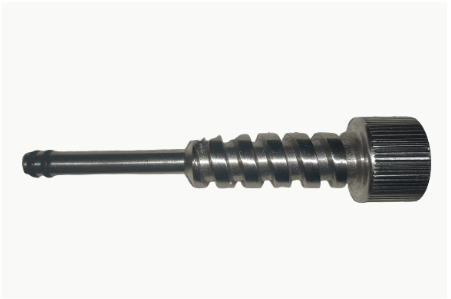

3. Drill another hole 3-4" down the crack, tap a bullseye and mount your Long Crack Slider and injector also filled with a low viscosity windshield

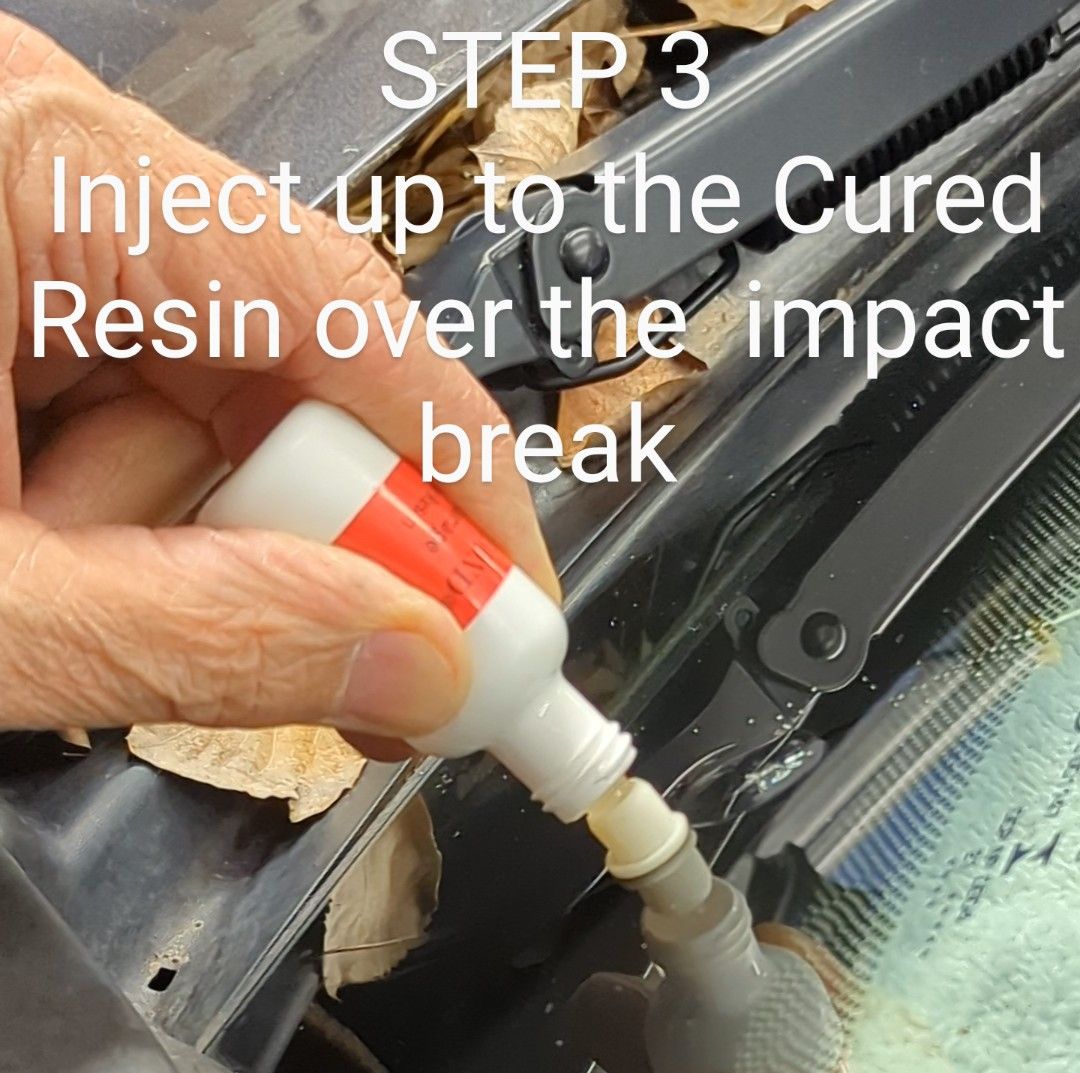

4. repair resin (about 4 drops) and leave it on vacuum. This is creating a pushing and pulling action between the two injectors

5. When the resin from the 1st Crack Master (Classic) has reached the 2nd Crack Master switch the 2nd Crack Master injector to pressure.

6. Remove the 1st Crackmaster. Drill another hole 3"-6" down from the 2nd injector and repeat steps 3, 4 and 5.

7. When completely filled, tab and cure. * A 10" crack would require 3 drill holes.

THE "Y" CRACK

The "Y" Crack may look like a scary repair, but once you think about it as two separate cracks, it becomes quite simple. The "Y" crack off the side or horizontal can be repaired using any repair method. You will repair the bottom crack first stopping when it hits the joining crack and repairing the top section last. If you did the top portion first, you are taking the chance of getting resin into the bottom crack and preventing repair, or making it difficult.

- Repair the bottom crack first using any method and a low viscosity windshield repair resin and switching to a medium viscosity windshield repair resin. Stop at the apex or joint of the crack. Tab and cure.

2. Repair the top crack as you would a normal single edge crack starting with a low viscosity resin at the point, switching to a medium, or high or both,

depending on temperature. Tab and cure.

If the "Y" Crack is off the bottom, the 2 step works best.

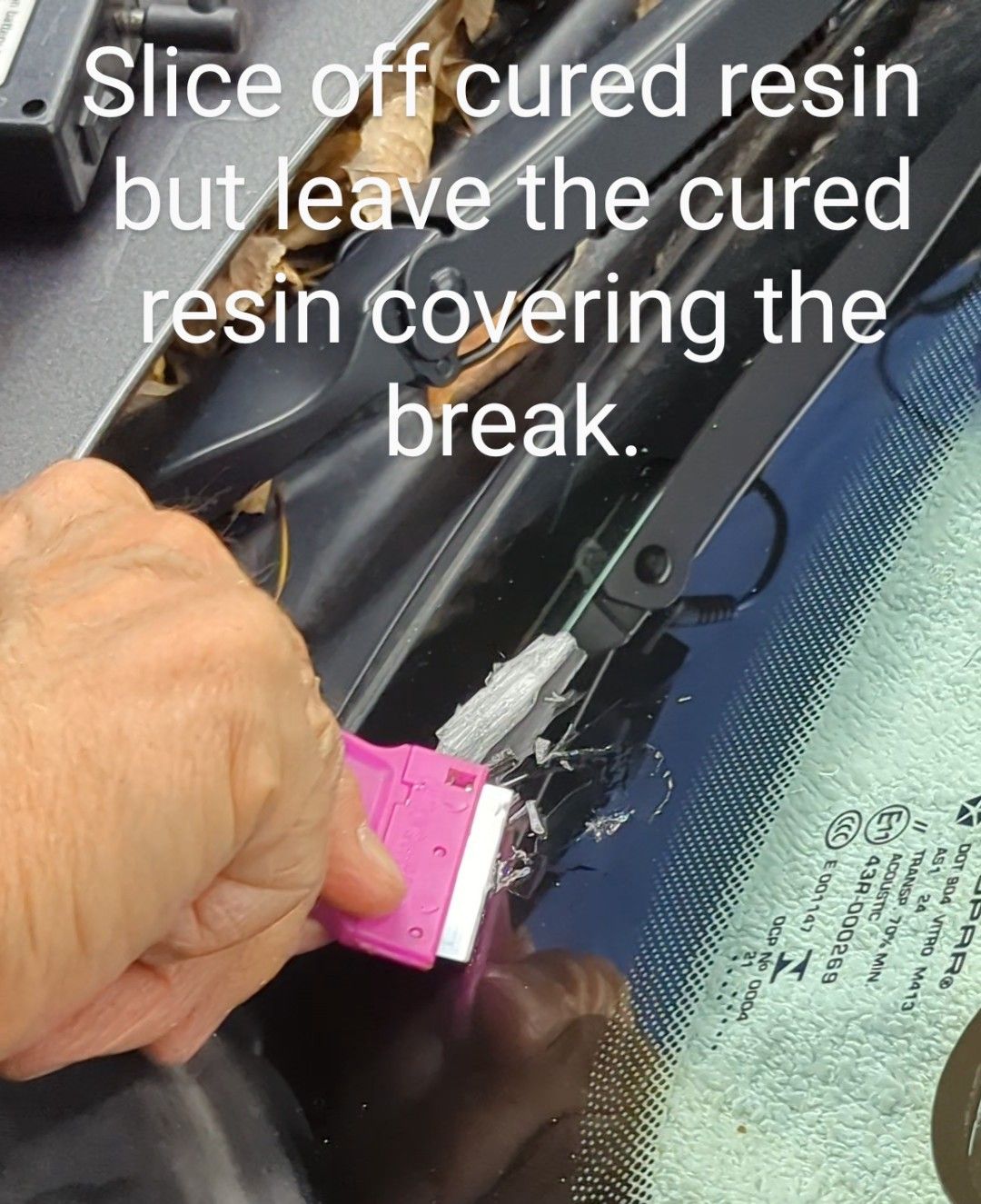

CRACK OFF A STAR OR BULLSEYE

What makes this repair difficult is filling the star or bullseye because you are unable to create a vacuum because the crack has surfaced. Therefore, these instructions focus on filling the star or bullseye. Separating the break as previously instructed above is the best method. Here are some more methods.

- If it is a small bullseyes roll a drop of 45 cps into the impact point, it will fill by capillary action while you are working on the rest of the crack.

OR

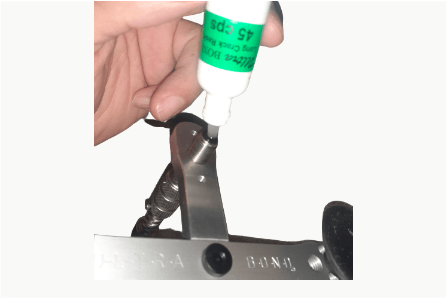

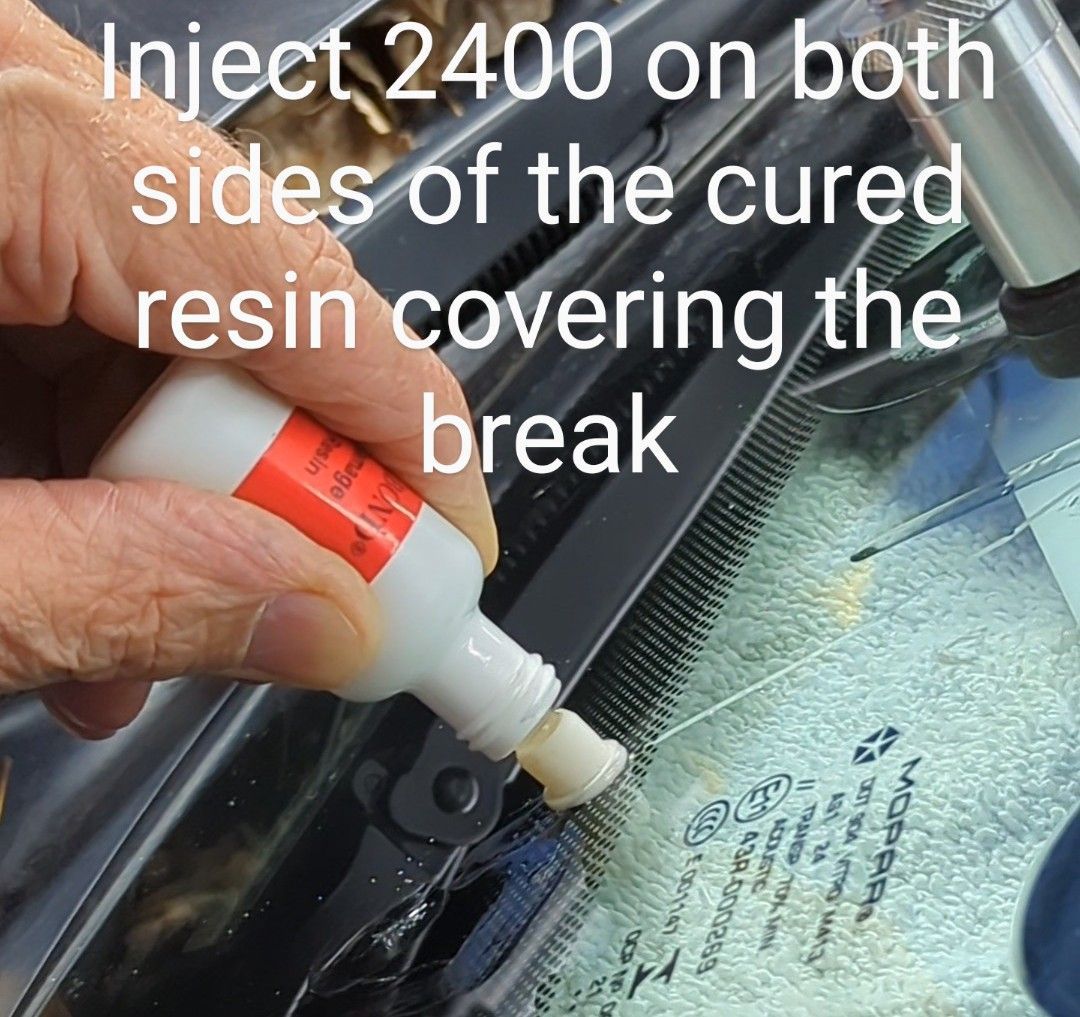

- After step 1, take your injector and fill it with 1600 or 2400 cps windshield repair resin and place in the structure. Mount it on the impact point on pressure and let it slowly fill. If the star does not fill, take your probe and flex on each leg of the star that is not filling. Manually pressure pushing and probe flexing simultaneously is fast and works well.

OR

- Refill the injector with 1600-2400 cps and place on impact point in the pressure mode without the structure. Manual pressure push the resin which should push the low viscosity resin to the tips of the legs.

IF

- By chance all of the legs of the star still do not fill, continue repair of the long crack and cure. Return back to the legs or areas of the star that did not fill and drill and tap a bullseye. Vacuum and pressure fill. Cure under pressure. Pit fill the drill hole, cure and clean up

REPAIR TECHNIQUE:"INJECTOR SLIDE"

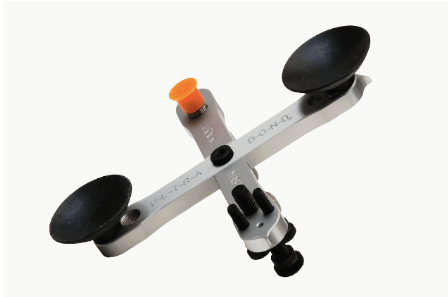

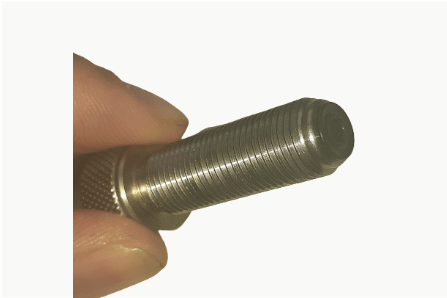

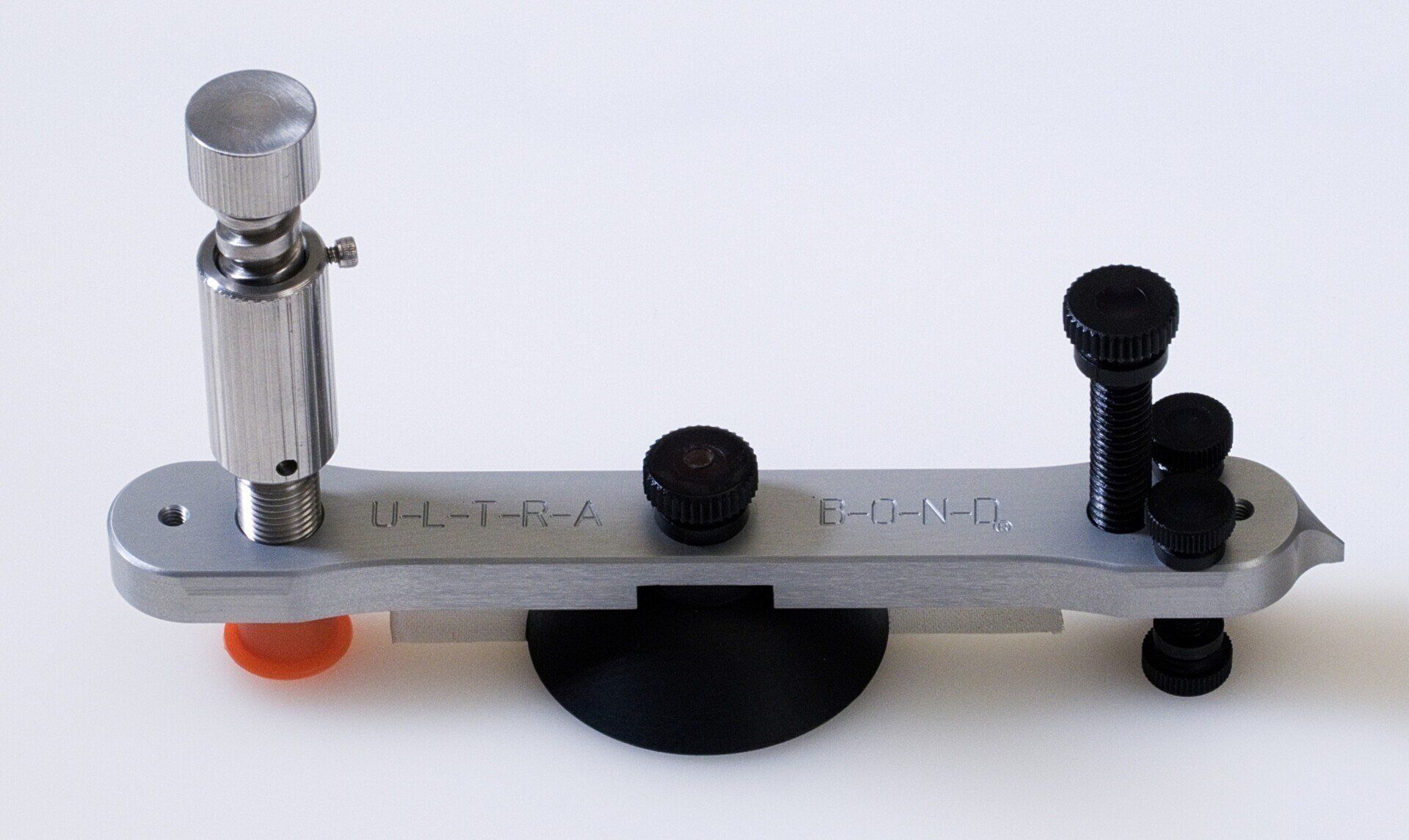

1. The "Injector Slide" does not use the Crack Master structure to hold the injector. Instead, hold the injector in your hand and slide it along the length of the crack as you inject the resin. This technique can only be used when your eye has been trained to see if the crack is open wide enough to allow the resin to enter and completely fill.

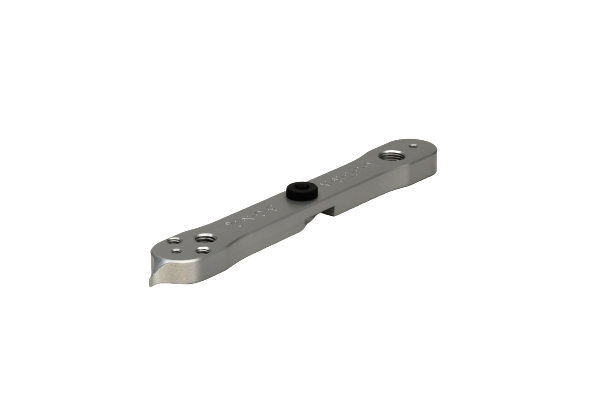

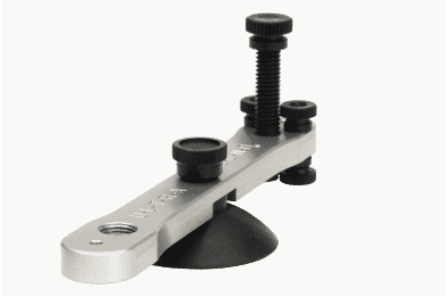

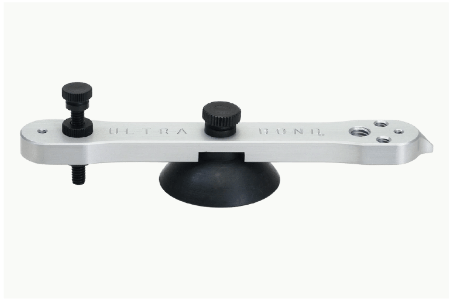

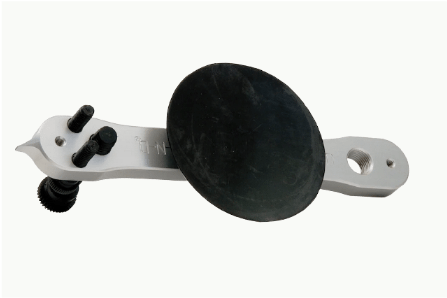

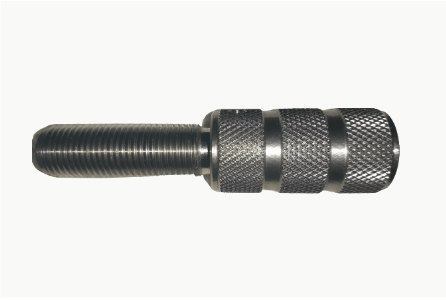

2. Use your long crack slider tool but remove the suction cup. Slide it from the edge in toward the point. Use 1600 if the impact point is the typical pinhead size chip. Use 2400 if the impact is a star or combination break.

WINTER TIME REPAIRS

Wintertime makes long crack repair a delicate operation and because the cracks are surfaced, your resin will be exposed to the atmosphere. Resin will flow into the crevices of the crack most effectively and bond to the glass when at room temperature and above. If the resin gets cold it will not flow into the crevices or bond to the glass as well. Try to heat the glass and use the heating port by placing a soldering iron into the hole in your injector body to keep your resin warm. This will help, but best results are obtained indoors during the cold winter months. Use the Priming method. The Primers flow into the little nooks and crannies while the thick resin adds the cohesive strength. Be sure your windshield repair kit has all the windshield repair resins and windshield repair tools to handle the winter months.

RULES OF THUMB

- Always fill the crack with the thickest possible windshield repair resins according to the temperature (check bottle labels).

2. If mobile, you MUST use true shade.

3. Take extra care on a hot windshield, it is sensitive and damage spreads easily.

4. If you have more than one crack or break, work from the bottom up, otherwise resin could drip from the first repair into the second damage curing before

you can repair it and blocking an easy flow of resin.

5. Warm a cold windshield slowly with the defroster bringing it to a warm temperature.

6. If you need to flex on a cold windshield, do the point first. Drill a hole at the point and fill about ½" of the crack and cure. Turn on the defroster and warm

up the windshield. DO the remainder. This will help prevent the crack from spreading when you flex the glass.