Wherever you choose to advertise, be consistent with it. Potential customers will begin noticing your ad and you need to be there when they need you. You are offering a new and unique service and you have to educate them.

A good way to preserve your cash flow is to establish accounts with your advertising sources. Although they may require an up-front payment for your first ad, you are billed thirty days after you have been advertising and the bill is not due for another thirty days, giving you sixty days to make money on the ad before having to pay for it.

Basic Sources of Advertising:

- Internet

- Company Website - a must

- Google Adwords

- Yellow Pages - check your area. getting obsolete in some markets

- Newspapers

- Weekly Advertising Circular

- Radio

- TV

- Direct Marketing - best and most lucrative for chip repair

Market Study:

For all forms of advertising, you can find independent surveys that give you the most relevant demographic and consumer data available for your area. The studies indicate how many people are listening to the radio, watching t.v. or reading the newspaper. Ask media representatives for their survey and compare it to an independent one to get the most accurate information. Your local chamber of commerce should be able to direct you to those resources.

Newspaper:

Your market survey should tell you which newspapers were read within the time period they survey. Some will also show the number of days read by the largest percentage of customers, their age group, and income.

Newspaper generally ranks second for best source of income. You need to select a consistent period to advertise (once a week, once every two weeks), and try to be consistent where your ad is placed. Use your logo each time your ad runs, or at least be sure the heading remains the same. Customers will begin to recognize you by that logo or heading. Your wording can change as often as you want - offer a special, but something must remain the same every time (logo). Your representative will be helpful in letting you know which days have the most readership, which can vary with seasonal sports. You may want to be in the sports section on Mondays during football season or in the food section on coupon days.

The benefit to the newspaper is that the customers are usually more qualified. They have read your ad, are curious about your service, and more than likely, have a repairable break on their windshield when they call. Also, the newspaper seems to draw the customers will new vehicles that have been damaged and that are expensive to replace.

Weekly Ad Circular:

They can work, are cheaper than the newspaper, but may require more repetition or a larger ad. It's a good place to do coupon advertising. Be sure to include an expiration date. Display ads are better than reader ads; a picture is worth a thousand words and it's hard to describe a new service in 1 or 2 lines.

ADDITIONAL SOURCES OF ADVERTISING:

Radio:

Market surveys for radio change more often because the stations are constantly changing their format. Probably the best surveys will be the ones you get from each station. You want to know when they have the largest listening audience, how many stations there are in your area, and what percentage or the total listening audience is listening to that station! Radio can be expensive and risky.

TV:

From your market surveys find out how many people watch the local news and what time and stations are the best. Unless you can find a widely watched, inexpensive cable time slot, TV might not reach a large number of people on a consistent basis. However, because of the additions of cable and satellite, some areas have dropped their rates for local stations. If you have local ABC, NBC, CBS or FOX affiliates this is a very god source of advertising.

INTERNET:

Have a website made, optimize and submit to the search engines. Call Rich for contents for your website and recommendations.

HELPFUL HINTS FOR ADVERTISING

An ad must get the message across at a glance if in print. Don't get too wordy. Try pictures, but make sure something in your ad stays the same all the time and is recognizable.

The heading should be the main message you are trying to convey "THAT CRACK CAN BE FIXED!" "LONG CRACK REPAIR" "DON'T REPLACE IT". Your business name should not be the biggest, but can be included in fairly large print if your name is descriptive "FIX A CRACK WINDSHIELD REPAIR".

The body of your ad should have the details and information needed for a person to make a fast decision. Keep it short and clear to the reader; they are not a repair technician. If you are the only person in the area doing windshield repair, refer them to the yellow pages if you have an advertisement there.

For t.v., showing what you do is the best. For radio, too many words can cause the listener to tune out. If you can relate the ads to the customer, they are more likely to watch or listen. Does your area do road repair or chip sealing that causes breaks in windshields? How did you get a crack in your windshield? By asking people how they got their break, you'll get an idea for a commercial.

A magnetic or hand painted sign on the side or back of your vehicle is a great and inexpensive form of advertising. Use the logo you are using in your advertising - recognition.

PROSPECTING

Business to Business

There are two cost-effective ways to prospect, cold calling and telephone solicitation. We have enclosed a partial lit of potential business customers that you may be able to reach in person or by telephone. Get the word out to your friends, neighbors, and businesses you currently use for different services (mechanic, lube & tube).

1. In person (cold calling)

The most productive way to prospect would be to do it in person. Set yourself a schedule to call on five businesses per day. It is advised to do no more than 10 and no less than 10, but you should do it every day. Consistency. The reason you don't want to do more than 10 calls a day is that you may get discouraged if you are turned away too often.

When entering a business you will need to speak to the person in charge of vehicle maintenance. Ask if they have heard of windshield repair versus replacing. Let them know how much it could save their company (up to 75% most of the time). Offer to do a free repair - you choose the break. If they pick, they will pick the largest and worst break, which could be dirty.

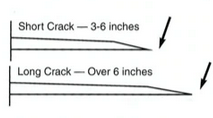

Offer a special fleet rate and a schedule where you would come in once a week or once a month to check their windshields. If they have heard of windshield repair or if they already have someone doing their repairs, ask them if they are satisfied with the work being done and then inform them that your service offers long crack repair, which can save them even more. Leave a card, magnet, brochure, pen, anything you think they might keep, read and remember you by.

2. By telephone

Telephone solicitation is more difficult because it will take you longer to reach the person who makes the decisions or is in charge of vehicle maintenance. Make 10 calls a day every day if this is the avenue you choose.

PHONE PITCH

The customer calling will most likely not know anything about windshield repair. Therefore, your first step is to take control of the conversation. Never let the customer take control. You are the one with the knowledge.

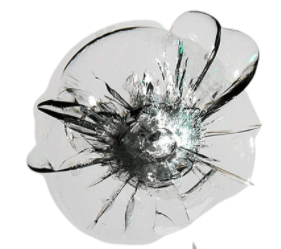

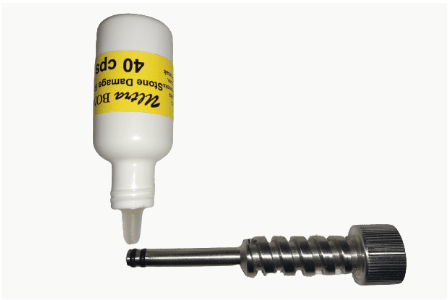

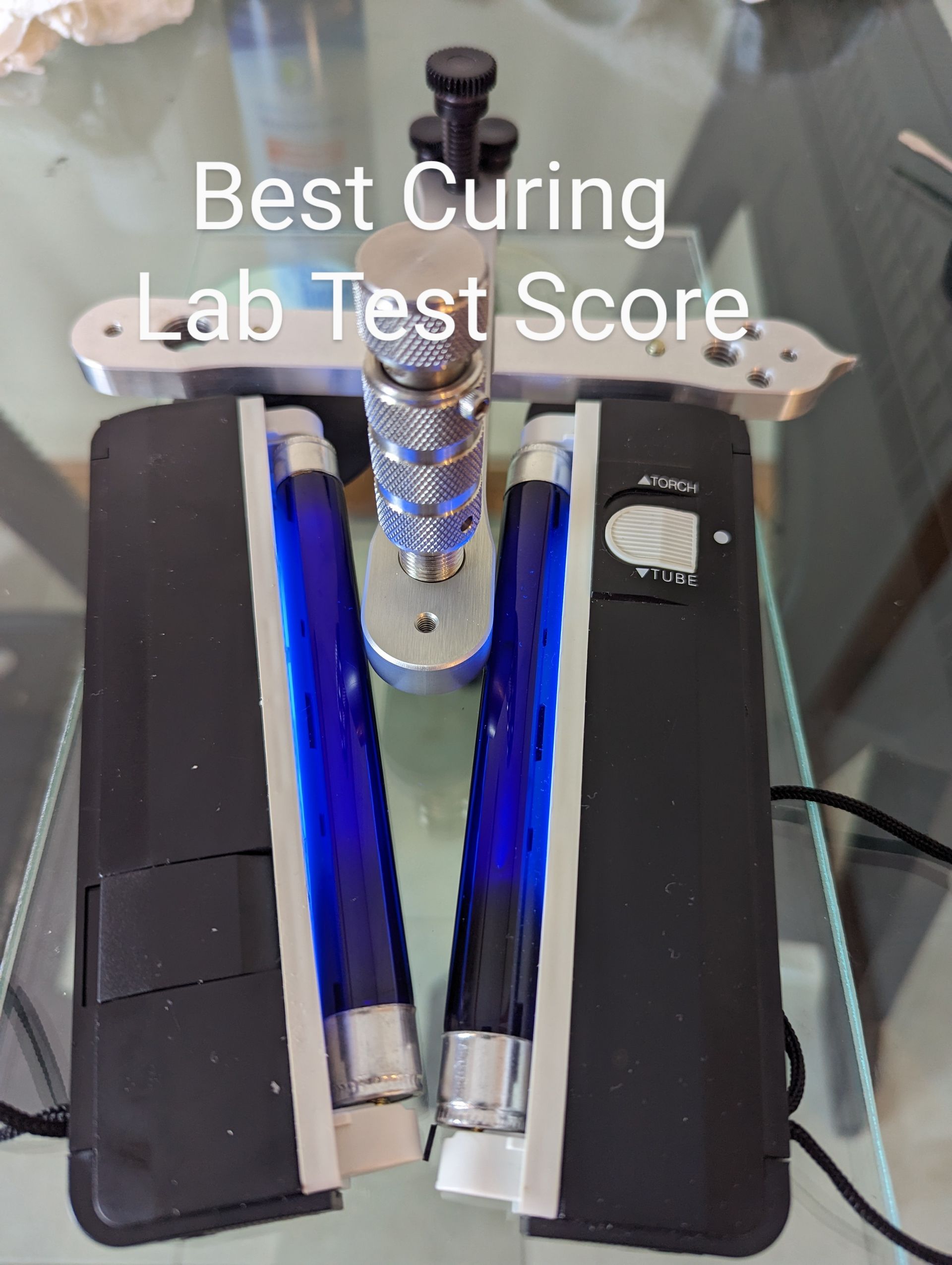

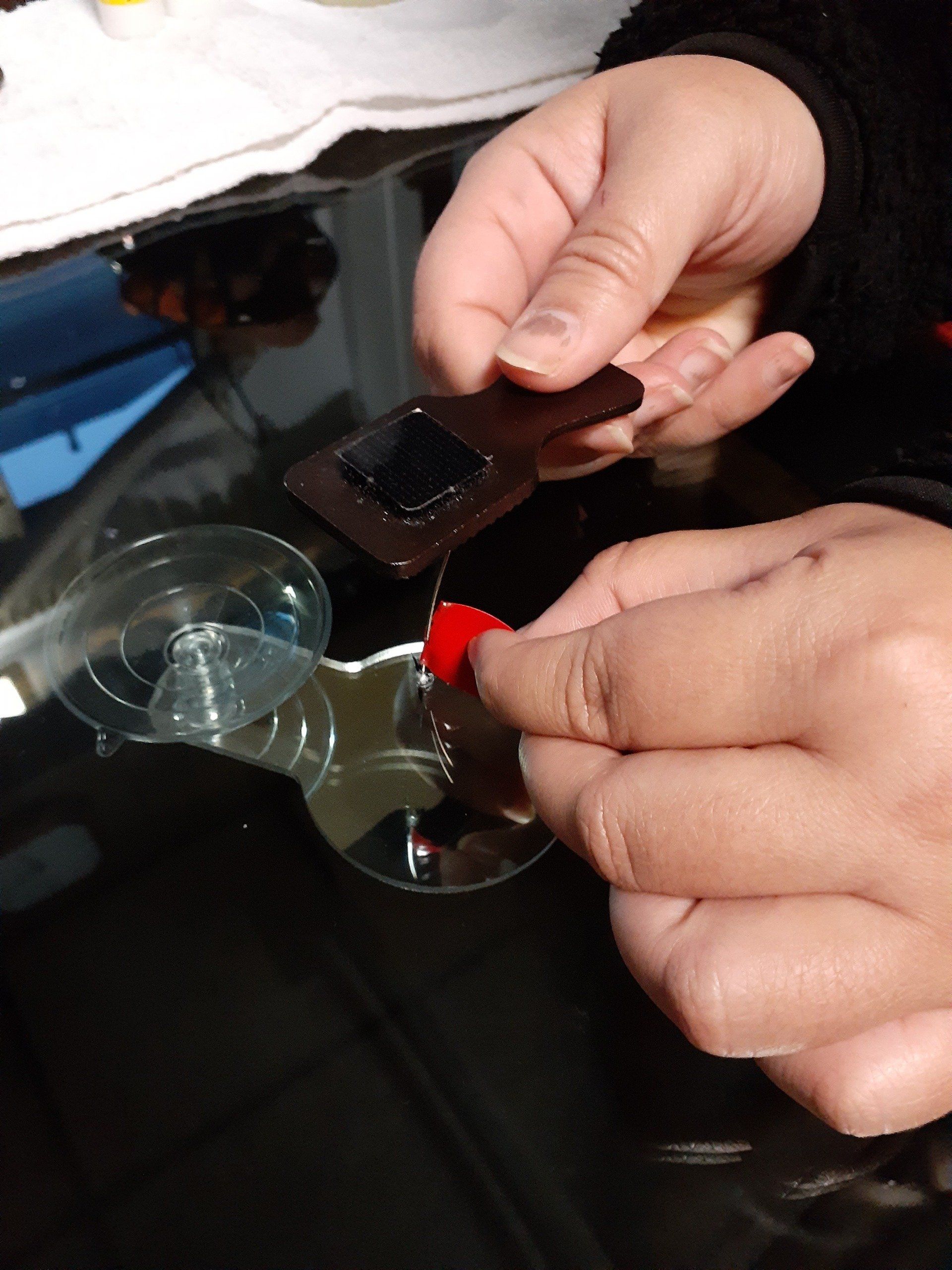

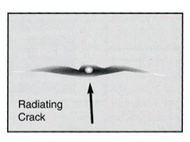

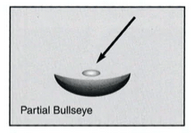

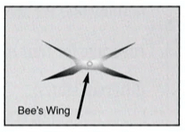

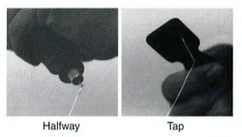

Ask: Have they ever heard of windshield repair before? No? Describe what you do. "We inject clear glass adhesive (or resin) into the break which will fill in the gap and prevent the break from spreading any further. It will significantly reduce the appearance of the damage and restore the strength.

Ask: Could you please describe the break, what caused it, and how long ago did it occur? (By asking questions, you show that you have to have specific information to perform the repair - knowledge, you are qualifying the repair, and showing interest and concern to the customer). Proceed: "Your windshield is repairable and the cost is only $__________. Let them know about your shop service or mobile service. The customer will usually just say "uh huh" or "okay", which is your sign to close the deal.

Proceed: "We have tomorrow available at (time) or (time). If they seem hesitant, give them a little more information - your written warranty, how long cracks have been repaired, etc. If you are sure their insurance company covers repairs, tell them to bring their insurance card and the repair may cost them nothing - but be sure you are correct. You want to get them in the shop. With the insurance networks sending customers to their own list of vendors, you have to keep the control in your hands. Once the customer is in your shop, the network can't make them leave. Go for the close again.

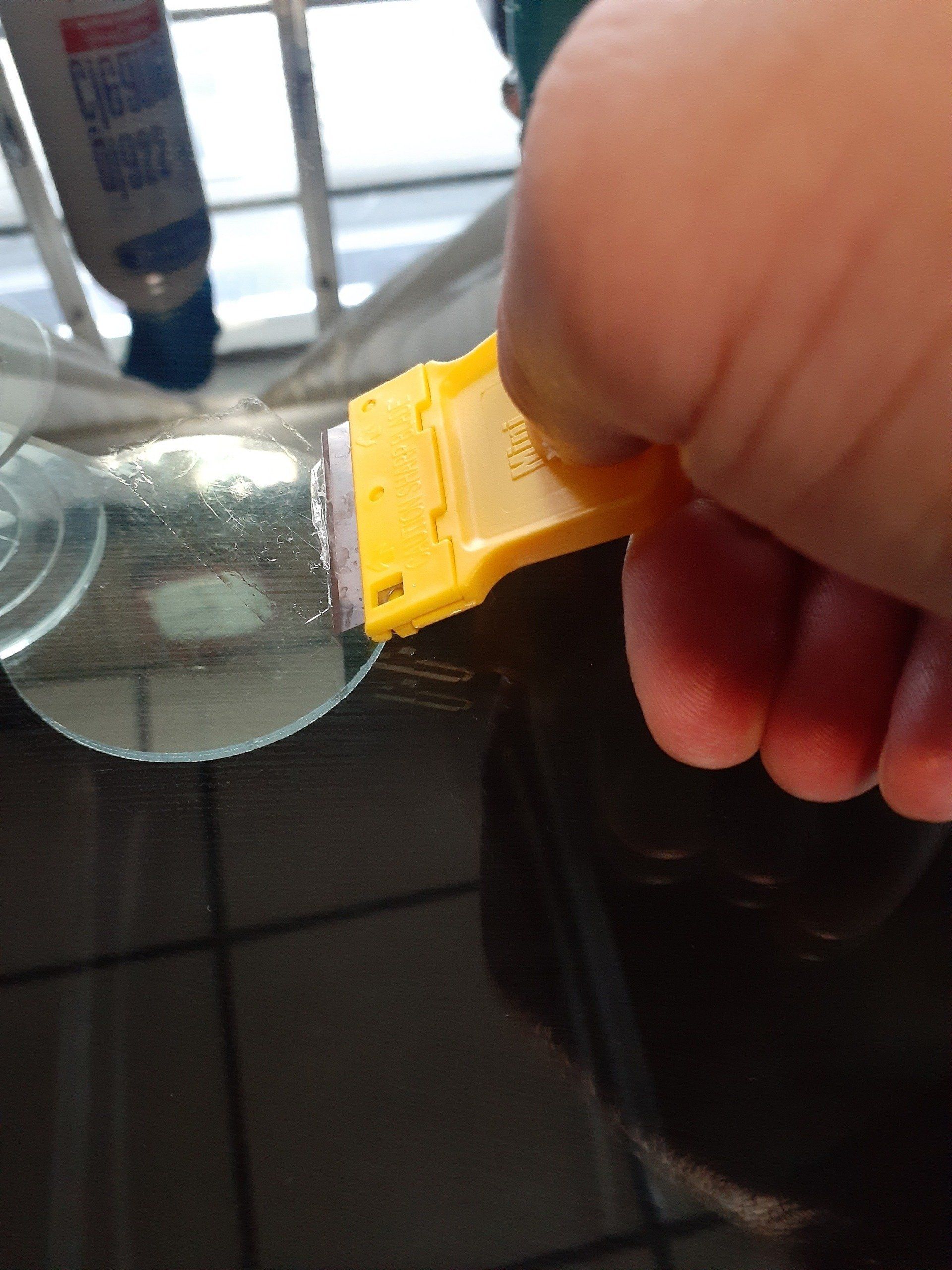

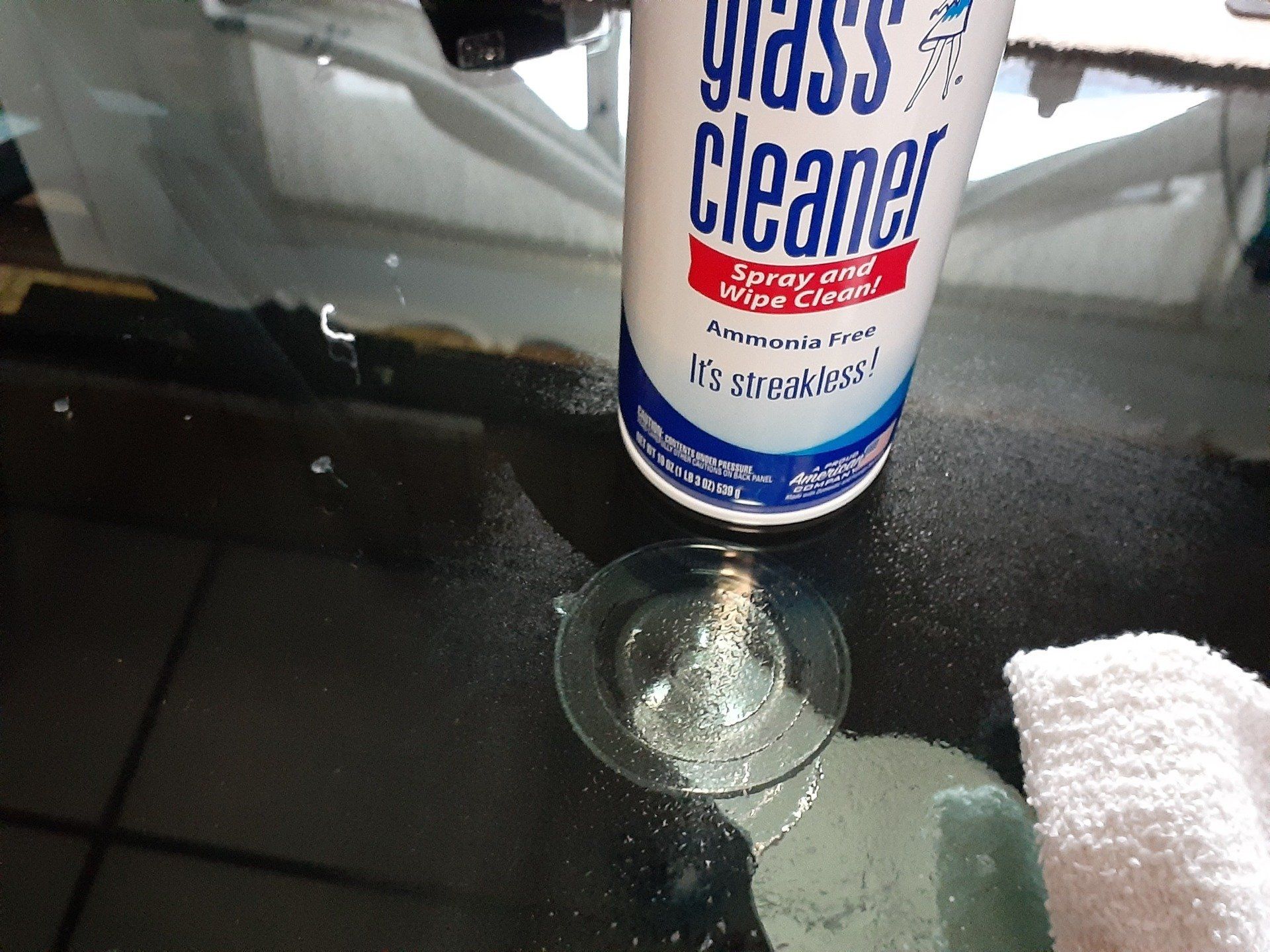

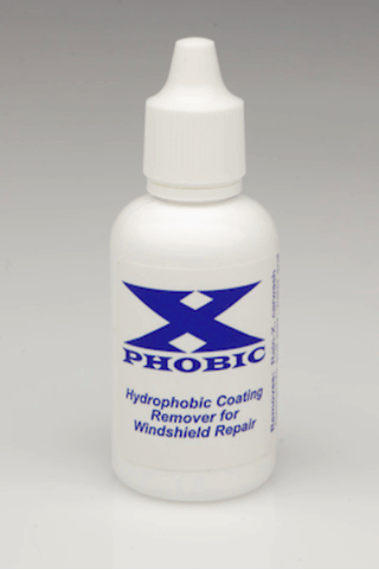

Confirm the date and time of appointment. Be sure you tell the customer not to wash the windshield prior to coming in - you will clean it for them when you are done. Water may prevent the resin form adhering to the glass (showing off your knowledge again). If performing the repair via mobile service, show the customer how much you care about their car. Protect it. Get it into true shade, use a big towel to protect their car and clean the windshield thoroughly when you are done.

Always repeat the procedure to the customer before performing the repair, have them sign the warranty, making sure they are clear that the break will not disappear completely. You are performing a repair service - not giving them a new windshield.

DIRECT MARKETING - GET INTO A PARKING LOT - Some grocery and department stores will rent you a space in there parking lot. You can also see if a car wash, car repair , tire store, etc. will allow you to be in their parking lot for a fee (preferred) or offer them 1/4 of your gross income as they are providing the customers. Surveys have shown one out of every three vehicles has repairable damage. You will only need nine-ten customers per day to see a six figure annual profit giving 1/3 to the owner. Better for you to get a flat rental fee so they do not know you have struck gold in their lot.