Professional Windshield Crack Repair Kits

Lab Test Reports

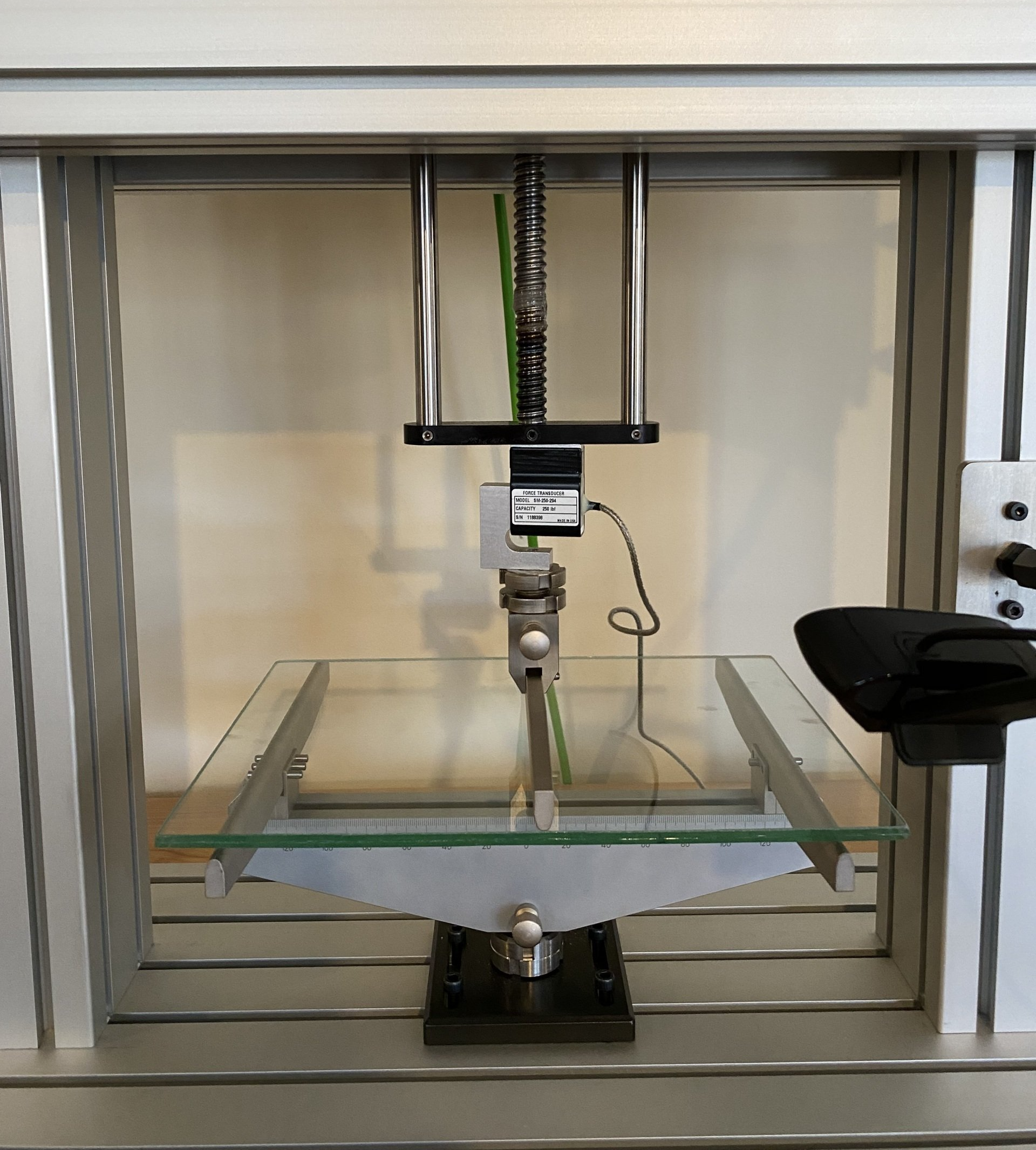

The American Windshield Repair Standard is called the Repair of Laminated Auto Glass Standard (ROLAGS). It includes the same strength test all glass manufacturers use for new windshield glass, that being the Standard Test Method for Strength of Glass by Flexor. This test is by two methods, the 4-Point Bend and the 3-Point Bend. Mechanical Strength by 3-Point Bend Test is used for Windshield Repair Systems. The 3-Point Flexural/ Bend Test is the DNA of a Windshield Repair. This test places the stress right on the repair. Here are the Results of Ultra Bond's Windshield Repair Kits, Tools and Resins.

REPORT

The ANSI Windshield Repair Standard in the United States is named the American National Standard Institute; Repair of Laminated Auto Glass Standard; ANSI/NWRA/ROLAGS 001-2014 (ROLAGS). This standard was originally developed in 2007 and then updated in 2014 by the United States Auto Glass Repair and Replacement Industry Associations. It includes Lab Test recommendations for those that manufacture or sell windshield repair kits, windshield crack repair kits or windshield repair resins. Globally all other countries with a windscreen repair standard recognize the Mechanical Strength by 3-Point Bend as THE test for windshield repair because it measures, (1) Compression, (2) Tension, (3) Shear, (4) Adhesion and (5) compares the repaired laminated glass to new laminated glass all in one test.

The purpose of these safety, exposure and restoration tests is to protect the public and the buyers of windshield repair kits and resins so they can know if and to what degree they are restoring the third most important safety device in a vehicle. If you repair windshields you need to be sure that you are not compromising your customers safety by only using lab tested products per the United States Auto Glass Industry recognized and court recognized testing.

Here's how the test works

- Laminated glass samples are cut into 12-inch x 6-inch. Three undamaged samples are tested as new glass and the average score of those three undamaged samples is the benchmark for the repaired samples to be compared to. For the crack repair test a glass cutter is used to crack the glass across the center and then split by hand to cause it to crack from edge to edge. For the chip repair test a spring-loaded center punch is used to create a star-break or combination break in the center of the glass. The samples are then repaired with the manufacturer's tool, resin, methods and curing method. The samples are then placed into a freezer followed by an oven for three rounds call The Resistance to Thermal Cycling Test. After three rounds of exposure the samples are ready to be stressed until they break by the 3-Point Bend Test. The repaired side is placed in the down position so to put that layer of glass into tension, while the top undamaged side is getting compression. This will cause the repaired sided to break first in most instances. Once the repair fails or the glass fails a dip appears in the graph and that is the repair's score.

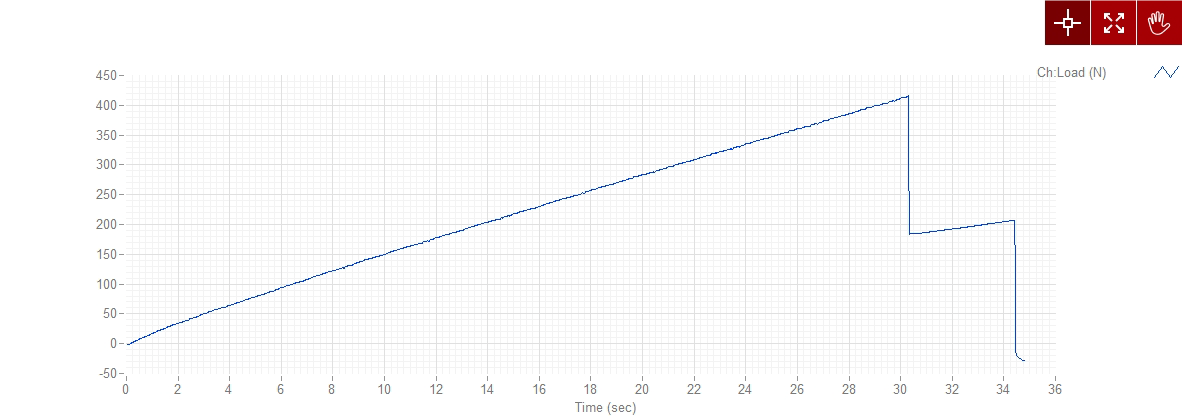

How to Read the Graph of the Lab Test Report

The Graph Tells the Story.

- The numbers on the left are the measurement of the load in Newtons.

- The bottom numbers are the time of failure in seconds.

- The first dip in the graph is when the repair failed and that is the score of the repair.

- The second dip is when the other layer of glass failed or broke.

Lab Report Graph of an Inferior Windshield Chip Repair

In this Graph the new laminated glass is the top line. The other three below the new glass line are the three repairs. This graph shows the repair restored only 43% of New Laminated Glass Strength. It did not restored the Break-Pattern and it reduced the Time of Failure.

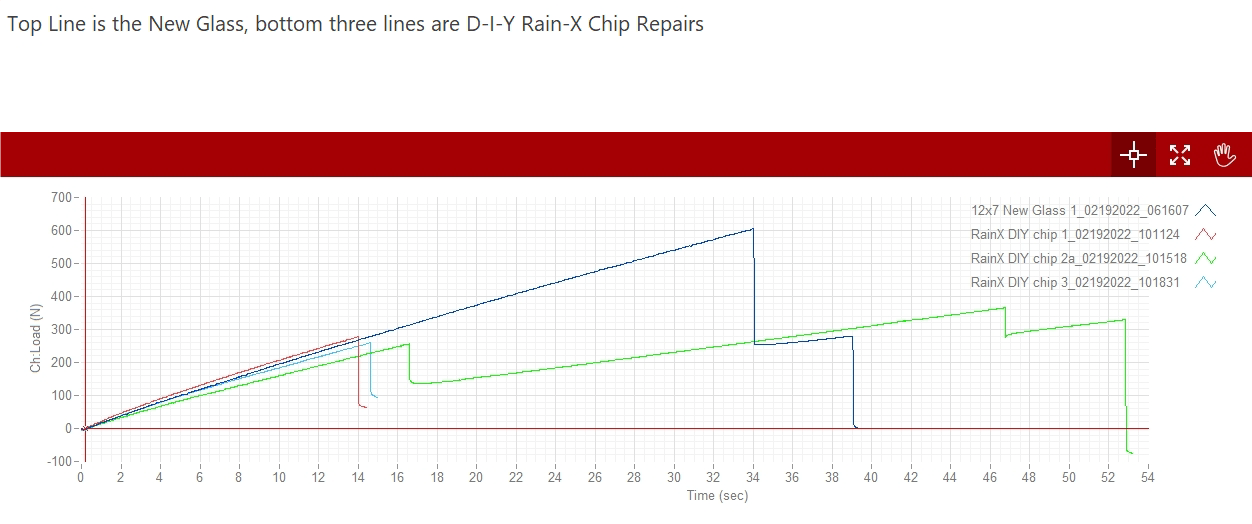

Lab Report Graph of a Superior Windshield Crack Repair

In this Graph the new glass is the line on the bottom. The other three on top are the three repairs. This graph shows the repair restored over 100% of Strength, restored the Break-Pattern and extended the Time of Failure. Most important was Consistency, which means low standard deviation.

Specimen ID - Crackmaster 1, 2 and 3

Break Type - Star-Break/Combination Break

1. Tool - Ultra Bond Crack Master Wonder Bar Bridge (2-bar bridge)

2. Resin - Ultra Bond 100 Resin

3. Method - Flex and Release; Vacuum & Pressure; Cure Under Pressure

4. Curing - 2 minutes under pressure, 1 minute for the pit.

5. Curing Light - 6-volt battery fluorescent 365 nm (cost of $29.95).

Test 1 Results and Conclusions

Control Score: New Laminated Glass

Conclusion: 136%

Ultra Bond Chip Repair Tool with 100 Resin is 136% of New Laminated Glass Strength

Maximum Stress - 3,976 psi

Average Load - 101 Lbs.

Test Score: Ultra Bond Repaired Laminated Glass

Maximum Stress - 5,370 psi

Average Load - 136 lbs.

Specimen ID -Clear400Crack 1, 2, and 3

Ultra Bond passed all of the ROLAGS recommended visual, safety, exposure and strength lab tests with a score of 152% new laminated glass strength in 2016. Those lab test results can be linked to on the bottom of this page under Windshield Repair Lab Tests. The purpose of this test here was to use the ROLAGS thermal cycling exposure rather than the QUV weathering. QUV is heat, moisture and UV (Florida weather). QUV has never had any detrimental effect on Ultra Bond repairs. In fact, the mechanical strength of Ultra Bond repairs was higher than unexposed repairs. Because of this Ultra Bond began using thermal cycling for exposure followed by 3-point bend many years ago. So this test is to compare the mechanical strength after QUV versus Thermal Cycling. Thermal Cycling is placing the samples in a freezer at 0 degrees F and then removing the cold glass and hitting it with a heat gun at 240 degrees F until the repaired side hits 150 degrees F, three times. This simulates a windshield sitting outside in the winter at 0 degrees F and then getting hit with the defroster air which is over 200 degrees F.

Test 2 Results and Conclusions

New Glass Control Samples:

Maximum Stress - 3,976 psi

Mean Load – 101 lbs

Score after QUV - 152%

Ultra Bond Crack Repair 400 Resin

Maximum Stress – 4,730 psi

Mean Load – 120 lbs

Score after Thermal Cycling - 120%

Conclusion: 152% – 120 % .

Ultra Bond long crack repair method with 400 resin is over 100% of new windshield glass strength no matter what the weather exposure.

400 resin is unbreakable, meaning the repaired crack remained intact with both layers of glass breaking simultaneously.

Test 3

Drilling and Tapping a Bullseye to Stop a Crack From Spreading

Specimen ID - Green 1, 2, and 3

This is the crack test but where the samples were cracked half away across and a hole was drilled in front of the crack (called the point) and a mini bullseye tapped with a needle and tapper. The tip of the crack connects into and terminates in the mini bullseye. This is known to permanently stop a crack from spreading. The drilled hole and mini bullseyes was filled with Ultra Bond’s 45 resin and the rest of the crack filled with Ultra Bond’s 400 resin. The 45 resin in the point was cured under pressure.

Test 3 Results and Conclusions

New Glass Control Sample:

Maximum Stress – 3,721 psi;

Average/Mean Load – 95 lbs.

Crack Repaired with Drilled Tip:

Maximum Stress – 4,995 psi;

Average/Mean Load – 126 lbs.

Conclusion. 132% of New Laminated Glass Strength using Ultra Bond Crack Resins.

The drilled hole and tapped bullseye remained intact. Drilling and tapping a mini bullseye in front of the crack at the point permanently stops the crack from spreading and increases the strength of the overall crack repair.

Break Type = Star-Break / Combination Break

- Tool – Ultra Bond (2 bar) Wonder Bar Bridge

- Ultra Bond 40 Resin

- Method –Flex and Release; Vacuum & Pressure; Cure Under Pressure

- Curing – 2 minutes under pressure, 1 minute for the pit.

- Curing light – 6- volt battery fluorescent 365nm (cost $29.95)

Test 4 Results and Conclusions

New Laminated Glass Control Sample: Average Load = 664 Newtons

Ultra Bond Repaired with 40 CPS Resin:

Average/Mean Load =719 Newtons

Conclusion: 108% New Laminated Glass Strength

Ultra Bond Chip repair using the Wonder Bar Bridge and the Flex and Release Method with 40 resin is 108% New Laminated Glass Strength. This is the

only low viscosity chip repair in the industry that hits 100% of new windshield strength.

Break Type = Star-Break / Combination Break

- Tool – Ultra Bond (2 bar) Wonder Bar Bridge

- Ultra Bond 20 Resin.

- Method –Flex and Release, Vacuum & Pressure; cure under pressure

- Curing – 2 minutes under pressure, 1 minute for the pit.

- Curing light – 6- volt battery fluorescent 365nm (cost $29.95)

Test 5 Results and Conclusions

New Glass Control Sample:

Average Load – 590 Newtons

Ultra Bond Repaired with 20 CPS Resin:

Average Load – 543 Newtons

Conclusion: 92% of New Safety Glass Strength.

Ultra Bond Chip repair using the Wonder Bar Bridge and the Flex and Release Method with 20 resin is 92% of New Laminated Glass Strength.

Break Type = Star-Break / Combination Break

- Tool – Ultra Bond (2 bar) Wonder Bar Bridge

- Ultra Bond 50 Resin

- Method –Flex and Release, Vacuum & Pressure Cure Under Pressure

- Curing – 2 minutes under pressure, 1 minute for the pit.

- Curing light – 6- volt battery fluorescent 365nm (cost $29.95)

New Glass Control Sample:

Mean Load – 437 Newtons

Ultra Bond Repaired with 50 CPS Resin:

Mean Load – 481 Newtons

Conclusion: 110% New Glass Strength.

Ultra Bond Chip repair using the Wonder Bar Bridge and the Flex and Release Method with 50 resin is 110% New Laminated Glass Strength. This is the second highest, low viscosity chip repair in the windshield repair industry.

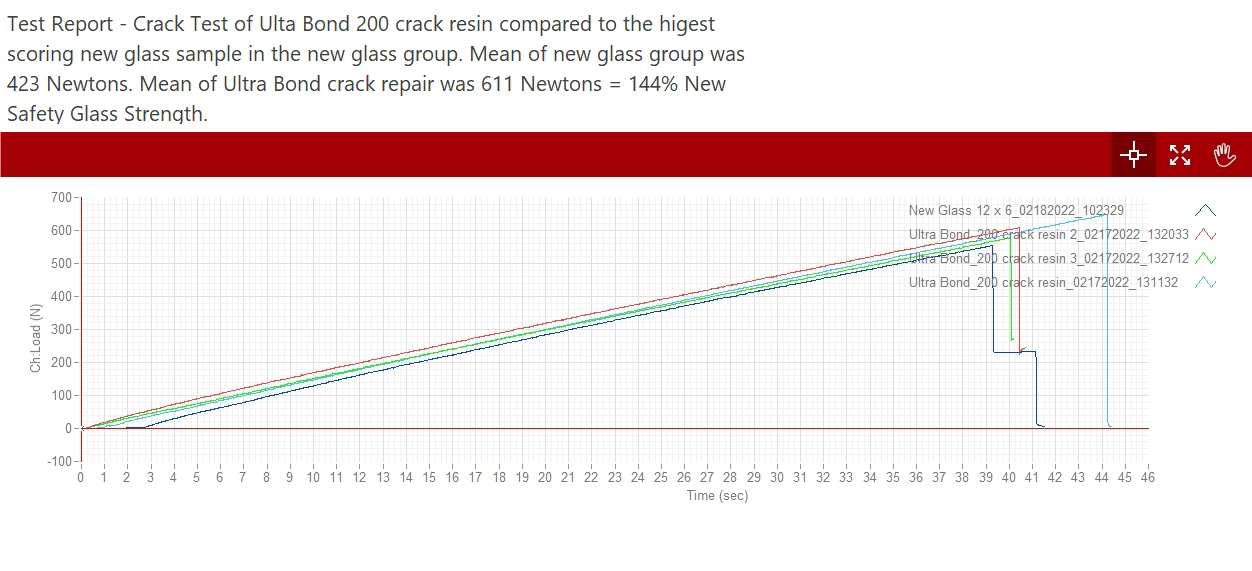

Break Type = Crack

- Tool – Ultra Bond Wonder Bar Long Crack Slider Tool and two Crack Openers

- Ultra Bond 200 Resin

- Method – flex open crack with crack-openers and inject with Long Crack Slider Tool

- Curing – 3 minute with Fluorescent 365 nm

- Curing light – 8 watt, 12” fluorescent 365nm (cost $89.95)

Test 7 Results and Conclusions

New Glass Control Sample:

Mean Load – 423 Newtons

Ultra Bond Repaired with 200 CPS Resin:

Mean Load – 611 Newtons

Conclusion: 144% of New Laminated Glass Strength

Ultra Bond Long Crack Repair using the Wonder Bar Tools with 200 resin is 144% of New Laminated Glass Strength.

As with all Ultra Bond crack resins the repaired crack remained intact with both layers of glass braking simultaneously.

This is the third highest long crack repair score in the windshield repair industry.

Break Type = Edge Crack

- Tool: Long Crack Slider, Injector Slide or Pressure Syringe

- Ultra Bond 1600 Edge Crack Resin

- Inject at the edge toward the point until it stops flowing

Test 8 Results and Conclusions

Test 8 Results and Conclusions

New Glass Control Sample:

Mean Load – 287 Newtons

Ultra Bond Repaired with 1600 CPS Resin:

Mean Load = 438 Newtons

Intact after a Rollover Crash, Intact after FMVSS 205 Impact and Penetration Tests

Conclusion: 150% - Unbreakable in a Rollover Crash and Federal Impact and Penetration Tests.

Ultra Bond Long Crack repair using 1600 resin is

unbreakable and 150% of New Laminated Glass Strength. Repaired crack remained intact in 4-point bend, 3-point bend, a real-world rollover crash and FMVSS 205 - ANSI/SAE Z26.1 Impact and Penetration tests.