Objective

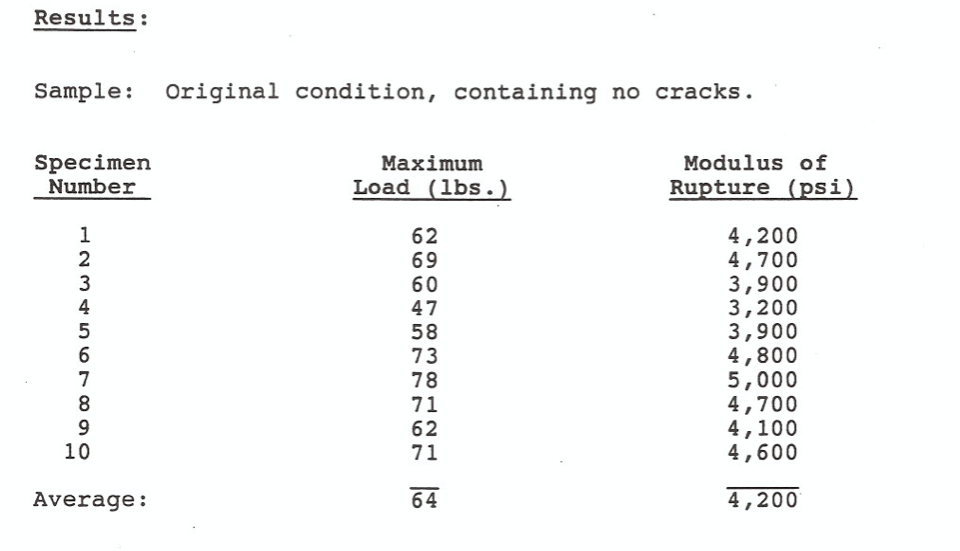

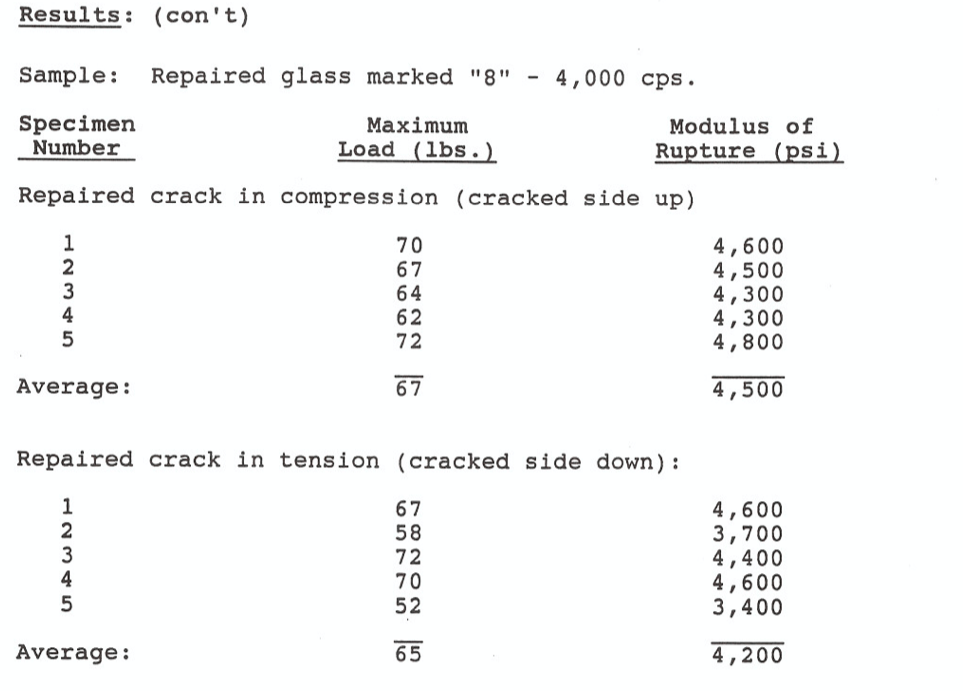

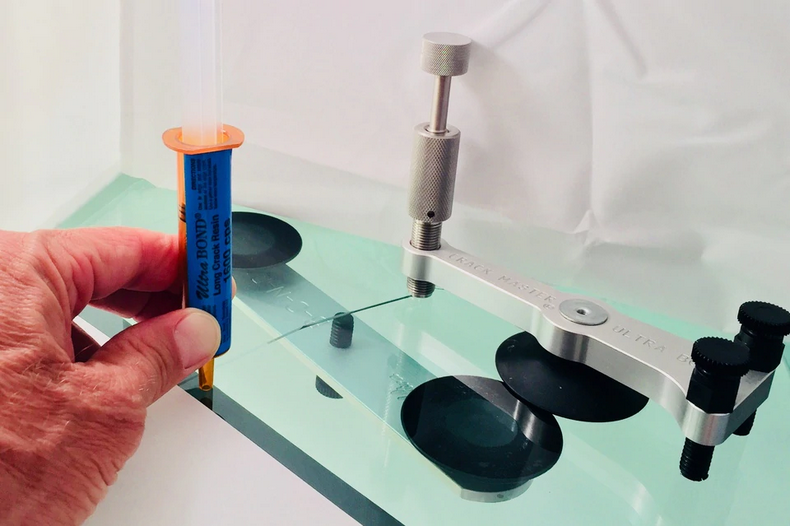

The purpose of this project was to determine the physical characteristics of the submitted repaired laminated glass by performing impact and penetration tests in accordance with ANSI/SAE Z26.1-1990 and flexural strength tests in 'accordance with ASTM C 158-84.

References

1. Conferences and correspondence with Mr. Richard A. Campfield Commencing November 16, 1993.

2. ANSI/SAE Z26.1-1990, "American National Standard for Safety Glazing Materials for Glazing Motor Vehicles and Motor Vehicle Equipment Operating on Land Highways-Safety Code".

3. ASTM C158-84, "Standard Methods of Flexural Testing of Glass (Determination of Modulus of Rupture)".