JULY 2007 WINDSHIELD CRACK REPAIR JOURNAL

Understanding How Weather Temperature Affects Windshield Repair

In this Issue we will discuss

- New Xtra Bond Windshield Repair Adhesion Promoter

- New Spray-On Edgeguard

- ANSI Approves ROLAGS

- Hot and Heavy - Edge Crack Resin Special - Buy 2 get 1 Free

- Ultra Bond Market Survey Published in Auto Glass Magazine

XTRA BOND

Most adhesive applications call for pre-treatment of the surface and for the surface to be roughed-up or sanded to increase adhesion. This was not possible with windshield crack repair because the cracks we bond are sub-surfaced or inaccessible for manual treatment. We use acrylic acid to achieve a chemical bond to the glass because we did not have the option of pretreatment. Ultra Bond has changed that. Proper chemistry will allow us to etch the glass surface for increased adhesion. That is what Xtra Bond does. Xtra Bond is a chemical combination that: etches the glass for increased mechanical bond, increases chemical bond, evaporates and, does nothing to the laminate. You can use it on any repair, especially star breaks and combination breaks with cracks extending beyond the bullseye that are in the defroster area. In fact it works as a primer or pretreatment for any glass adhesive application including windshield replacement.

How do you use it? Inject it into the break and let it evaporate. Placing your injector in the vacuum mode increases the speed of evaporation by itself and even faster with heat.

Another application method is to place one drop of Xtra Bond on a Q-Tip and press it on the impact point, filling the break by capillary action.

NEW Edgeguard In a Spray-Can

Every vehicle in your market is a prospect for our new Spray-On Edgeguard. It is easy to apply to any vehicle and is available to all our customers. This process uses the Xtra Bond as the primer and then two light coats followed by two medium coats for the protective coating. The labor comes in masking off the windshield and moldings when the windshield is already installed. We recommend coating the frit area only since 86% of edge cracks have an impact point in the frit area. We plan to release the product at $15.95 per can. One 10 ounce can will do two windshields. The time to do one vehicle is 45-60 minutes depending on your masking time. The vehicle can be driven one hour after the last coat. If you are applying onto a replacement windshield it will take twenty minutes and it should be sprayed the day before install.

ROLAGS APPROVED BY ANSI

The Repair Of Laminated Auto Glass Standard is now an ANSI Standard. This standard was not initiated because of any safety, structural or scientific problems within the windshield repair industry like AGRSS was for the windshield replacement industry. This was strictly politics.

Having authored the United States Windshield Repair Guidelines in 1995 we welcome this document since there is nothing in this document that is not in the United States Windshield Repair Guidelines. Ultra Bond will continue to follow The United States Windshield Repair Guidelines (USWRG) which is based on facts, evidence and science; calls for repair resins to meet the same federal required standard of a new windshield; calls for windshield repair resin manufacturers to disclose the mechanical strength of their resin; references all documents used; tells the truth as to repairable damages and; is user friendly with graphics so that a State Inspector can inspect a repair as well as a consumer and in fact, some state DMVs have used this document for this purpose.

How long of a crack will we repair? Ultra Bond will continue to advertise crack repair up to 18-inches long because that is the length of over 90% of repairable cracks. We will repair what the consumer chooses to repair when we know from our expertise that it is repairable, i.e. not contaminated, regardless of length which, 70% of the time, will fall within the ROLAGS 14-inch recommendation.

What is the major difference between the USWRG and ROLAGS documents? The driver viewing area. In the ROLAGS the driver’s viewing area is larger but more permissive to repairs in this area and the length of crack (uncontaminated) is 14-inches, strictly for political reasons. The United States Windshield Repair Guidelines does not restrict by length but by contamination, because that is the determining factor as to whether a crack is repairable and with an Ultra Bond crack repair generally the glass will fail before our resin does, even if the crack has gone from edge to edge.

The committee had originally voted (21 to 1) for 18-inches because of evidence presented by me, Rich Campfield, as to repairable damage and FMVSS 205 test results. Then it was voted in by majority that there would be no restrictions on length but it would include restrictions due to contamination, like the USWRG. However, because it is obvious that the networks are in bed with the insurance companies and have been adjusting windshield repair claims and determining repair or replacement by using a length of crack that has been obsolete for 17+ years, I and others on the committee believed that without any limitation/restriction on length the adversaries of the windshield repair industry (i.e., windshield and PVB manufacturers and networks) would continue to ignore our capabilities. Therefore, I decided to make a motion for a 14-inch repair limitation. We believed it was better to give them a compromised length to use, IF they even change their antitrust limitation.

The Australian Standard of 2000 is almost the same document as USWRG. Coincidence? Not in my opinion, especially since Ultra Bond assisted in submitting documentation for consideration. There is nothing in the Australian Standard that is not in the USWRG. The Australian Standard says 14-inches but makes it clear that cracks longer than 14-inches are repairable. The committee used 14-inches so they could refer the nay-sayers (windshield and PVB manufacturers) to the Australian Standard.

Overall we welcome any document that will help the windshield repair industry and prevent the consumers from getting deceived into unnecessary replacements.

ULTRA BOND’S MARKET SURVEY PUBLISHED IN AUTO GLASS MAGAZINE

Click above to see how large the windshield repair versus the windshield replacement market actually is.

More Related Windshield Crack Repair Journal Articles....

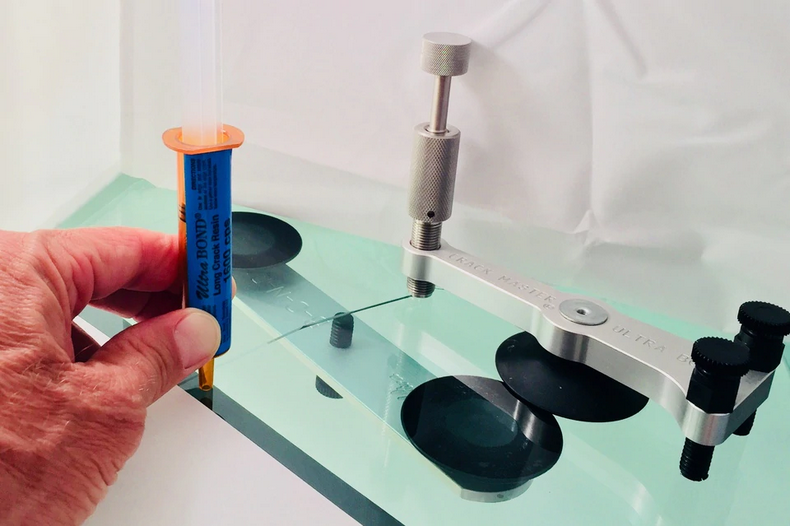

Ultra Bond Releases New Windshield Crack Repair Resin Injector...

Date: Nov 13, 2017

Author: Richard Ultra Bond

Category: Long Crack Windshield Repair

For the Edge area of a long crack windshield repair our new injector syringe pressure injects the edge area of an edge crack directly from the syringe. The edge area is from the edge of the windshield in 4-5 inches, this is where there is installation stress in the glass and the gap of the crack is the widest. Our two windshield crack repair resins used in the edge area are 1600 and 2400...

How Patent Trolls and Insurers Tried To Kill Windshield....

Date: Sept 17, 2017

Author: Richard Ultra Bond

Category: Ultra Bond Legal News

Large auto glass companies, glass manufacturers, and PVB manufacturers formed a committee through the National Glass Association in 1994 attempting to attack the safety of crack repair and to write a new standard to eliminate all professional and DIY windshield crack repair...

Date: Mar 21, 2017

Author: Richard Ultra Bond

Category: Ultra Bond Legal News

This action seeks damages and additional relief against Safelite under Section 43(a)(1)(B) of the Lanham Act, 15 U.S.C. § 1125(a)(1)(B), which prohibits, inter alia, any “false or misleading description of fact, or false or misleading representation of fact, which . . . in commercial advertising or promotion, misrepresents the nature characteristics, [or] qualities . . . of . . . goods, services, or commercial activities.”

NAVIGATE

CATEGORIES

HELPFUL LINKS

Ultra Bond, Inc. Toll Free: 1-800-398-2663 Email: info@ultrabond.com

2458 EAST MAIN STREET #B1 GRAND JUNCTION, CO 81501 USA

© 2021 Ultra Bond Windshield Repair